The Next Big Leap: How Structural Battery Composites Could Redefine Electric Vehicles

The science turning car frames into power sources

What if your car’s body wasn’t just holding the battery — it was the battery?

That idea sounds like sci-fi, but researchers around the world are inching closer to making it real through something called structural battery composites. In simple terms, these are materials that can both store energy and support weight — like turning your car’s frame, doors, and roof into one giant battery pack.

And if that happens, the entire design philosophy of electric vehicles could change overnight.

Why we need a Better Battery ?

Current electric vehicle batteries come with a set of well-known challenges — they’re heavy, bulky, expensive, and not as sustainable as we’d like. Battery packs can make up nearly a third of an EV’s total weight, taking up valuable space and limiting how designers shape the car. They’re also costly to produce because materials like lithium, cobalt, and nickel are both scarce and energy-intensive to extract.

That’s why the industry is starting to look beyond traditional lithium-ion pack designs. The goal is to find smarter, lighter solutions that integrate energy storage directly into the vehicle’s structure, reducing weight and complexity while improving efficiency.

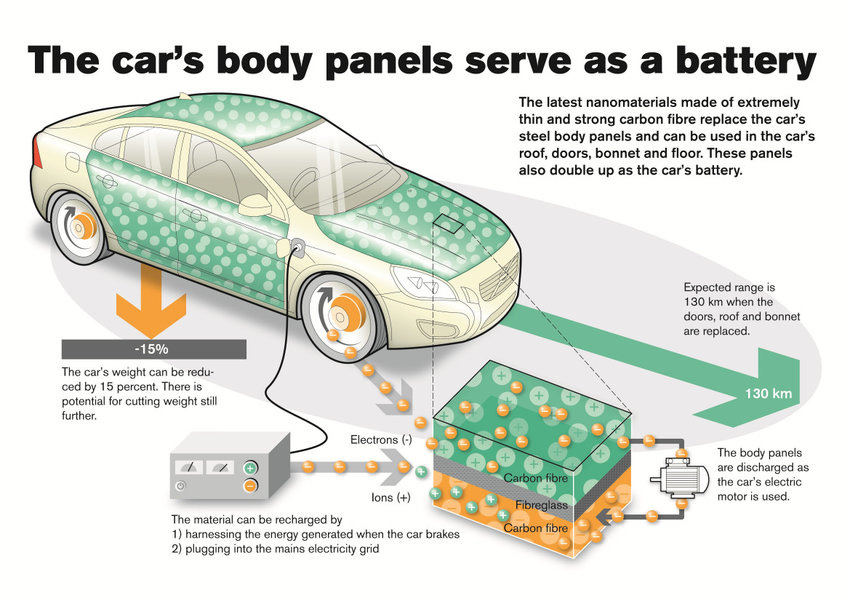

Leading this push are researchers at Chalmers University of Technology in Sweden, who’ve developed strong, energy-storing carbon fiber composites. Companies like Volvo have already begun experimenting with these materials in body panels, hinting at a future where the car’s frame itself could serve as its battery.

What Are Structural Battery Composites?

At their core, structural battery composites are multifunctional materials that can both bear mechanical loads and store electrical energy. They typically combine carbon fiber — which provides strength and acts as an electrode — with a solid electrolyte that allows ions to move between layers, much like in a regular battery.

In simpler terms, imagine a car where the roof, doors, and chassis aren’t just protecting the battery — they are the battery. This approach eliminates the need for separate, heavy battery modules, opening the door to lighter, more efficient, and potentially safer electric vehicles.

Recent Breakthroughs

While the idea of combining structure and storage has been around for over a decade, real progress has taken shape only in the last few years — and it’s moving fast.

Researchers at Chalmers University of Technology in Sweden have been leading the charge, developing new generations of structural battery composites between 2021 and 2023. Their latest prototypes achieved an impressive balance: around 25 watt-hours per kilogram of energy density while still being strong enough to bear mechanical loads. That means these materials don’t just store energy — they can also replace parts of the car’s chassis or body panels without sacrificing strength.

Much of this progress comes from advances in carbon fiber–reinforced polymers (CFRPs), which serve both as the structure and as an active electrode in the battery. These composites are incredibly lightweight yet mechanically robust, making them ideal for use in electric vehicles and even aircraft.

Another major step forward is the integration of solid-state electrolytes into these composites. Unlike liquid electrolytes used in traditional lithium-ion batteries, solid ones are non-flammable and more stable, which greatly improves safety and lifespan — two of the biggest challenges in EV energy storage.

Beyond the lab, big names are taking notice. Volvo has experimented with carbon-fiber battery panels that can power onboard systems, Tesla has hinted at interest in structural battery designs as part of its “cell-to-structure” philosophy, and Airbus is exploring similar concepts for lightweight, energy-storing aircraft components.

Each of these developments points toward the same vision: a future where batteries aren’t separate boxes tucked inside vehicles, but integral parts of their structure — making every gram count toward both strength and power.

Impact on Electric Vehicles

If structural batteries take off, EVs could:

Go farther — less weight means better range.

Get cheaper — fewer separate parts to build and assemble.

Be safer — solid electrolytes reduce fire risk.

Look cooler — imagine new design freedom when you don’t need a bulky battery pack underneath.

Challenges Ahead

Of course, it’s not all smooth driving ahead. Right now, structural batteries have lower energy density (they don’t store as much per kilogram) and are tricky to manufacture. Engineers also need to make sure these materials can handle years of stress, vibration, and crashes without losing capacity or safety.

As one researcher put it:

“You can’t just make the car a battery — you have to make it a safe, repairable, and affordable battery.”

The Future is in the Frame

The next decade could be wild. Picture EVs where the roof, doors, and floor all double as energy storage. Airplanes that charge through their fuselage. Even smartphones that ditch bulky cells for power-storing casings.

Structural battery composites won’t replace traditional batteries overnight, but they’re rewriting what’s possible in electric mobility. The day your car is its own battery might be closer than you think.

What do you think?

Would you trust a car that stores power in its body panels? Or does that sound a little too futuristic for comfort?

Let me know your take — because if this tech works, the entire EV world might have to rethink what a “battery” even means.

Stay tuned and comment your thoughts on this and view our previous posts in case you missed them.

🔗 Stay Connected

📌 Instagram: [Click to visit] → memes, quick takes & daily updates.

📌 Substack: You’re already here—check our previous posts, in case you missed them.

📝 Note: This space is for analysis, not advocacy. We break things down so you can think, not follow a script.

Having an issue with our post? Do mail us: teamib@substack.com